Access to safe food is the demand of daily life. Food Safety is a critical aspect of our daily lives that impacts our health and wellness. In the food industry, one significant framework that ensures the safety of the food is known as Hazard Analysis and Critical Control Points (HACCP). Worldwide, HACCP plan is developed to identify and control potential hazards in the process of food production.

Hence, the implementation of HACCP helps safeguard the global food supply chain. To understand the concept of HACCP, it is necessary to look at its definition first.

What does HACCP stand for in food safety?

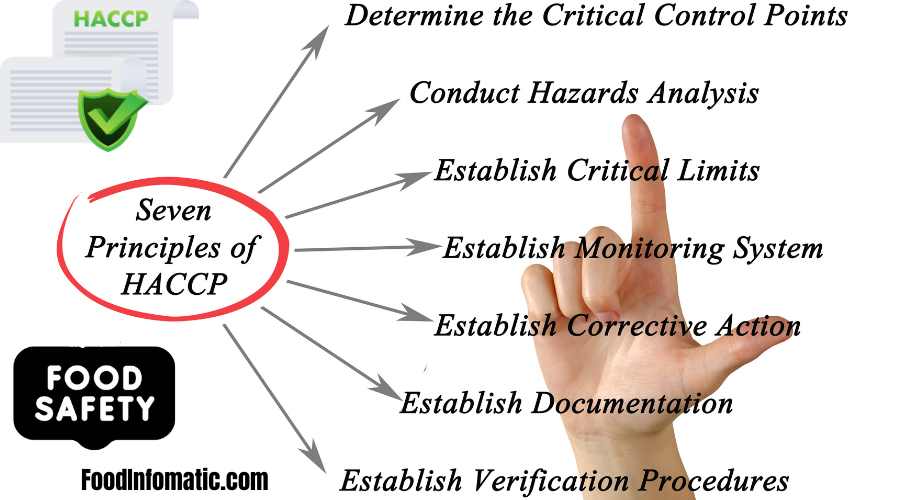

The full form of HACCP is Hazard Analysis and Critical Control Points. It is an internationally recognized systematic approach to identifying, evaluating, and controlling potential food safety hazards. In other words, this is a preventive management system designed to manage and ensure food products safety, from farm to table. There are seven basic principles of HACPP that must be followed for implementation of the HACCP (1).

Seven (7) Principles for HACCP plan

1. Conduct Hazard Analysis

This is one of the critical HACCP principles and involves listing the steps in the process and identifying the places where the likelihood of significant hazards is prominent. The HACCP team from the specific food industry will target the hazards that can be prevented, eliminated, or controlled with the help of the HACCP plan.

In this step, the justification for either adding or excluding the hazard is reported, and consequent potential control measures are identified.

Importance of first principle: It is essential to understand and analyze all potential hazards for developing an effective food safety plan.

2. Determine Critical Control Points (for food safety)

One of the most important HACCP steps is commonly called critical control point (CCP). It is a step where identified hazards require specific control measures. In CCP, controls are applied, which help prevent, eliminate, or reduce (to an acceptable level) potential hazards.

Here, the HACCP system utilizes a CCP decision tree for identifying critical control points in the procedure. It must be noted that a critical control point might involve controlling more than one food safety hazard. Alternatively, sometimes, more than one CCP is required to control only one hazard.

So, the processing steps and the control needed to ensure food safety determine the required number of CCPs.

Importance of second principle: Critical control points help in focusing on targeted interventions to ensure food safety.

3. Establish Critical Limits

In this process, critical limits for each critical control point are established. Generally, Critical limits are the acceptable (minimum/maximum) levels that need to be set for a biological, chemical, or physical parameter in order to decrease, stop, or entirely remove a hazard to food safety.

Usually, these limits are the factors such as time, temperature, pH, weight, or some other relevant measure. These limits can be established based on scientific literature and/or regulatory standards.

Importance of third principle: Critical limits must be strictly followed during food production, and if exceeded, it indicates a potential hazard that must be addressed immediately.

4. Implement Monitoring Procedures

To ensure that critical control points are consistently followed, the HACCP team describes monitoring procedures to measure the critical limits.

The process involves describing the process, frequency, and time of monitoring. The step also identifies the individual responsible for monitoring and taking measurements during the production process.

Significance: Regular monitoring ensures that the process remains within established critical limits, providing real-time data on the safety of food production.

5. Establish Corrective Actions

If there is some deviation from CCP criteria, corrective actions must be taken. It is essential to meet the standards established in step 3 of the HACCP plan. Moreover, the team will be responsible for ensuring the procedure needed to take corrective actions, preventing potential food hazards, and identifying the person responsible for taking corrective action. It is also essential to establish the corrective actions in advance as part of the HACCP plan.

Significance: Establishing corrective actions in advance ensures quick responses to any deviations and prevents the release of potentially unsafe products into the market.

6. Establish Verification Procedures

These are the activities (excluding monitoring) that assist in determining the validity of the HACCP plan and ensuring that the system is working in compliance with the plan.

This step involves identifying procedures, including critical control points’ auditing, review of record review, review of the prior shipment, product testing as well as calibration of important instruments.

Significance: Verification helps in establishing the reliability of the HACCP plan and ensures meeting the food safety standards over time.

7. Documentation and Record-Keeping

This last principle of the HACCP is about recording all information that could be utilized as evidence of safe food production. The records involve HACCP plan information, details of the HACCP Team, hazard analysis, the description of the product, relevant flow charts, the identified CCPs, the monitoring and corrective actions, employee training records, SOPs, and record-keeping and verification procedures. In short, the information should illustrate that established standards are being met.

It is also essential that the record-keeping and documentation process is simple to follow. The food industry is responsible for training employees on record-keeping procedures.

Significance of HACCP Principal 7: Documentation and record-keeping give a historical record of the safety measures taken, assisting in traceability and accountability.

Importance of HACCP plan:

All major national and international regulations require the implementation of HACCP in all food industrial activities involving the production, packaging, transportation, storage, or distribution of food produce. Thus, food industries are responsible for complying with regulations and supplying safe food to the markets.

For food companies, the application of food quality and safety standards is a challenging task. It is more difficult for small businesses where employees are also small in numbers. Interestingly, implementing HACCP principles will lead the firms to meet the market’s requirements and produce competitive food products.

However, applying the HACCP analysis, especially the establishment of CCPs and hazard identification, requires high skill as well as considerable knowledge from the management. The enterprise needs to nominate only qualified persons for such important tasks (2).

Further, food companies can also seek help from a food consultation company. Worldwide, there are third-party food consultation companies that already have dedicated teams of experts from different industries. These companies assist small and large companies in devising their HACCP plan, along with creating and maintaining vital documentation. These steps can help companies effectively manage their HACCP-related responsibilities.

In conclusion, HACCP is a necessary regulatory and preventive approach to food safety, food allergy, and chemical and biological hazards during food production, which could cause risky foods. It involved the procedures to reduce potential hazards to an acceptable level. But, the efficiency of HACCP depends on the proper deployment, usage, training, and monitoring mechanisms.